Remote Well Monitoring Using Creowave C-Site Technology

Maintaining well integrity is critical to safe and efficient oil and gas operations, especially in remote or hazardous locations. With today’s wireless IIoT technology, operators can monitor well conditions in real time, no matter how inaccessible the site.

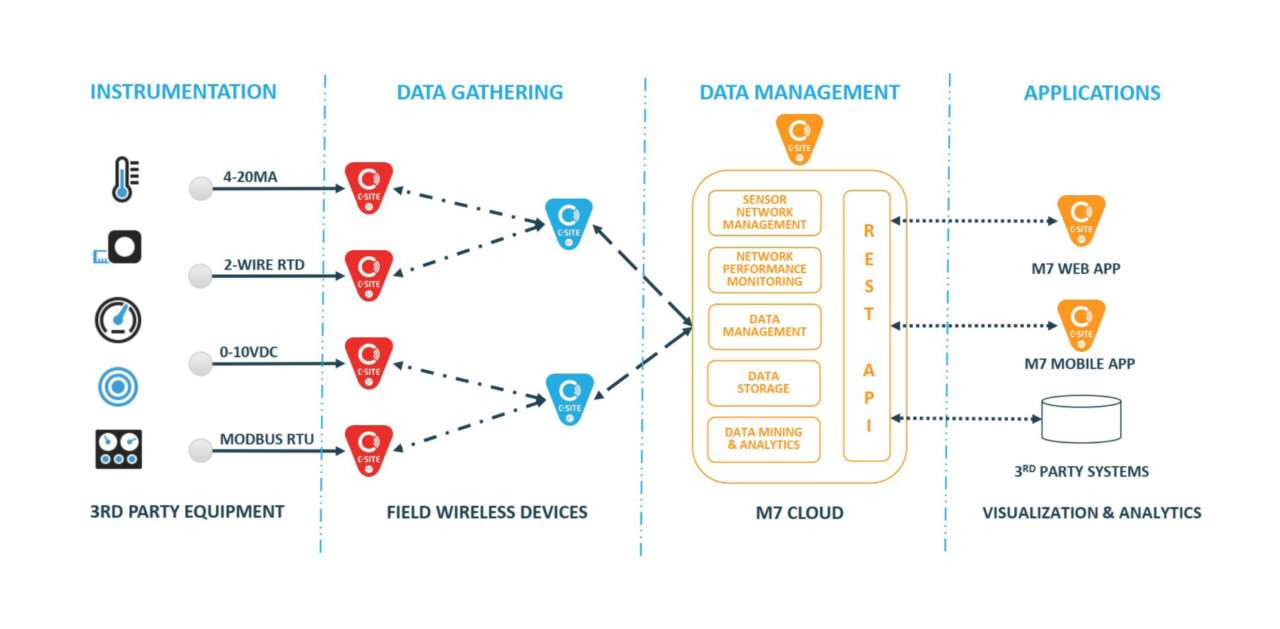

The C-site system combines ATEX/IECEx-certified wireless devices with the C-site M7 software to deliver continuous, remote monitoring and predictive insights. It gives operators constant visibility, real-time data, and full control, even from miles away.

By extending live monitoring to the field’s most challenging areas, the C-site system helps reduce downtime, cut maintenance costs, boost production, and improve safety, turning remote well monitoring into a strategic advantage.

The C-site Solution

Battery operated, self organising sensor unit

Intelligent access point for wireless sensor units

Complete management software

Use Case Example: Onshore Remote Well Monitoring at Oil & Gas Customer In The Middle East

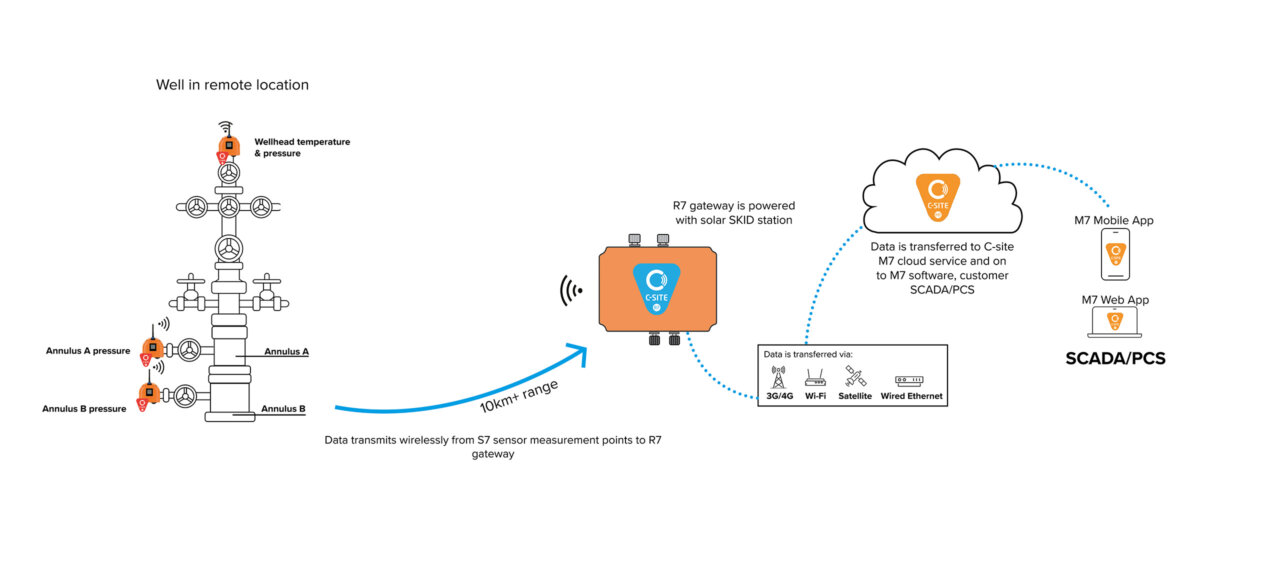

Several wells in remote and hazardous locations have been distributed over a large area. Distance between the wells is several kilometers. There is no data from the field, this means site visits and routine well inspections are needed. This is challenging due to no infrastructure and time and cost it takes for a person to check data on remote location.

Solution to this is to install C-site S7 measurement units to the wells to measure. Three S7 units are installed per well. The S7 units will measure wellhead temperature & pressure and annulus A & B pressure. A R7 gateway is setup with SKID solar powered station that powers the gateway – no need for energy infrastructure.

The well’s S7 pressure sensor detects a gradual pressure build-up in the annulus, which could indicate a potential tubing leak. This data is collected with the S7 measurement unit that transmits the data to the R7 gateway. Data communication from R7 unit to the M7 server via 3G/4G network by using R7’s integrated modem.

The M7 platform analyzes this data, comparing it with historical trends, and predicts that the well may experience a significant failure within a week. The system sends an alert to the operator, recommending an inspection and preventive action. The maintenance team, using the mobile app, inspects the well data and addresses the issue before it causes downtime or environmental damage.

Using the C-site system removes the need for manual data collection by providing real-time data which leads to early detection of problems and this in turn results in less damage, less cost.

How C-site Works

Designed for remote oil and gas operations, often in harsh desert environments with no existing infrastructure, our wireless IIoT S7 sensor units enable real-time, autonomous well monitoring without the need for external power or wired connectivity.

Powered by integrated solar panels, these units operate completely off-grid, making them ideal for isolated sites. They wirelessly transmit critical data over several kilometers to a centralized R7 gateway, which then relays the data securely to the cloud-based C-site M7 platform for analysis and visualization.

Key parameters monitored include:

-

Flowline Pressure & Temperature: Identify abnormal thermal behavior that could indicate casing failures or fluid migration.

-

Wellhead Pressure: High-resolution pressure transducers detect pressure fluctuations at the wellhead and casing, flagging early signs of integrity issues.

-

Annulus Pressure: Continuous monitoring of annulus pressure helps prevent tubing, casing, or downhole equipment failures.

With real-time wireless transmission and secure, encrypted data handling, this system enables operators to monitor the health of remote wells without needing to be physically present—enhancing safety, reducing operational costs, and enabling timely intervention from anywhere.

Remote Data Analysis & Alerts with M7 Software

Even in the most remote and infrastructure-challenged environments, the C-site M7 software delivers real-time, intelligent monitoring and alerting for oil and gas wells. Data transmitted wirelessly from field-deployed sensors is continuously analyzed using AI-powered predictive analytics, allowing operators to monitor well conditions from virtually anywhere.

The system identifies and alerts on critical anomalies such as sudden pressure spikes that may indicate blowout risks and gradual temperature deviations that can signal casing or tubing deterioration. Alerts are delivered instantly via email, SMS, or mobile app notifications, enabling rapid decision-making, even for wells located kilometers from the nearest operations center.

Proactive, Remote-Driven Maintenance

Thanks to machine learning algorithms, the M7 platform doesn’t just react, it predicts. Potential well integrity issues are flagged before failures occur, enabling targeted dispatch of maintenance teams based on real-time insights. This reduces unnecessary travel to remote desert locations, optimizes manpower, and boosts operational efficiency and production uptime.

In the event of critical alarms, such as high casing pressure, the system automatically initiates pre-defined safety protocols. Emergency teams receive precise GPS coordinates, and operators are guided through actionable steps via the mobile app, ensuring swift response even from afar.

Regulatory Reporting

All historical data is securely archived within the C-site platform, supporting automated audit trails and ensuring full compliance with regulatory standards, without requiring manual data handling or on-site access.

Key Benefits of The C-site System

Increased Production

By predicting maintenance needs and preventing equipment failures, C-site solution reduces unplanned shutdowns which in turn increases production time and profitability. Enhanced well & reservoir management could yield $3 savings in per barrel of oil equivalent, increasing sales.

Reduced Costs

Wireless C-site technology eliminates the need for extensive cabling, lowering installation costs and complexity. The M7 software insights improve decision-making and optimize maintenance scheduling. Predictive maintenance can reduce unplanned downtime by 20%-30%.

Enhanced Safety

Sensors enable early detection of issues (e.g. well leakage) & predictive analytics minimizes risks to personnel and environment. With less site visits safety & efficiency is increased.

Increased Efficiency

The M7 software’s AI and machine learning capabilities provide operators with actionable insights, enabling data-driven decision-making that increases efficiency. The system continually learns and improves, ensuring accurate and timely detection of issues which improves operations, e.g. minimizes engineering and field work.

Regulatory Compliance

Automated reporting simplifies adherence to industry standards and regulatory requirements. This reduces the administrative burden.

Ready to Transform Your Well Integrity Strategy?

Our wireless IIoT-based well integrity management solution exemplifies how modern technology can revolutionize traditional oil and gas operations.

By enabling real-time monitoring, predictive maintenance, and streamlined emergency responses, the system ensures enhanced safety, operational efficiency, and sustainability in the industry.

Talk to our team today and see how C-site can reduce risk, increase uptime, and future-proof your operations.